Electrical systems can be thought of as the lifeblood of modern civilization, integral to powering everything from homes and cars to entire cities and industries. They consist of complex networks of wires and components, woven together to create a functional whole. At the heart of these complex networks are electrical wire connectors.

These essential, yet often overlooked components, serve a multifaceted role. They not only enable the seamless flow of electricity but also provide crucial safeguards against potential hazards like short circuits and electrical fires.

Furthermore, they contribute to the overall efficiency and longevity of an electrical system by preventing loose or unstable connections that can lead to energy wastage. This article aims to demystify the world of electrical wire connectors. It covers the basics, delves into the different types and their unique features, and explores varied applications across multiple settings.

Additionally, it offers a deep dive into the considerations for selecting the right connector, the dos and don’ts of installation, safety measures, and even recent technological advancements in this field.

The Basics of Electrical Wire Connectors

Electrical wire connectors are specialized hardware designed to securely link electrical wires, facilitating the flow of electric current between different parts of an electrical circuit or system.

Think of them as miniature bridges that span the gap between disparate sections of wire, or between a wire and an electrical component such as a switch or an outlet. The primary role of these connectors is to provide a robust, stable connection that ensures both electrical connectivity and continuity.

Without these critical elements, constructing and maintaining stable and efficient electrical systems would be a monumental task, riddled with the risks of faulty connections and the associated safety hazards.

As this article unfolds, we’ll traverse the landscape of electrical connectors, focusing on the wide array of types available, their individual features, and the countless applications where they are not just useful but essential.

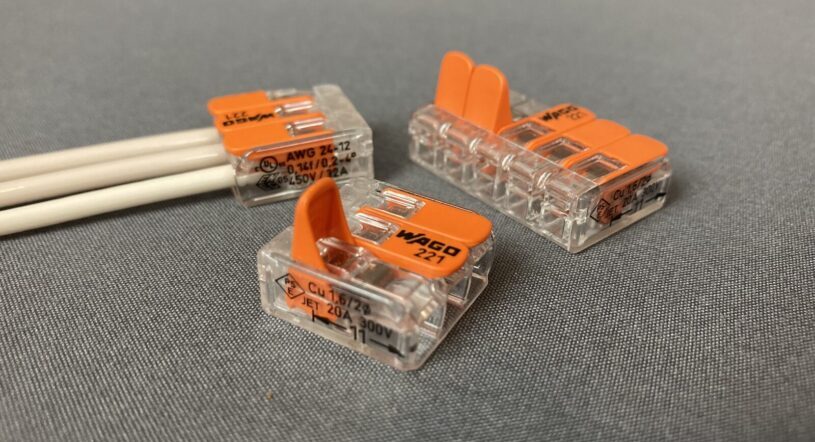

Types of Electrical Wire Connectors

Electrical connectors come in a plethora of forms, each tailored to meet specific needs and environments. First up are Butt Connectors, which are cylindrical in shape and designed for connecting wires end-to-end. They’re a go-to option for inline splicing and can be found in automotive applications, among others.

Next, we have Wire Nuts, easy-to-identify due to their conical shape. These are perfect for twisting together the ends of two or more wires, often used in household wiring projects.

Last but not least are Crimp Connectors, employed to permanently affix wires together using a specialized crimping tool. They’re particularly valuable in situations where soldering isn’t practical or desirable. To maximize the utility and safety of electrical systems, it’s essential to understand the specific applications and unique features of these various connectors. They aren’t one-size-fits-all solutions; each has been engineered with particular applications and environments in mind.

Uses and Applications

Electrical wire connectors are not confined to any single setting but rather find usage across a spectrum of applications. In Residential setups, they facilitate everything from simple tasks like setting up lighting fixtures to complex installations like home automation systems. In Commercial environments, these connectors work behind the scenes in HVAC systems, security setups, and even large-scale lighting applications.

When it comes to Industrial applications, they’re an integral part of heavy machinery, control panels, and expansive electrical networks that power manufacturing units. Given the critical roles that these connectors play across varied settings, it’s paramount to understand that each environment will require a specific type of connector, engineered to meet its unique electrical and safety needs.

Choosing the Right Connector

The task of choosing the right connector is not as straightforward as it might initially appear. It is a nuanced process governed by a range of factors, including but not limited to the size of the wire, the voltage requirements of the circuit, and even the environmental conditions where the electrical system is housed.

When it comes to Wire Size, it’s crucial that the connector and the wire gauge are compatible, as mismatched sizes can result in a weak connection or, worse, a safety hazard.

Similarly, the Voltage Rating of the connector must be appropriate for the circuit’s voltage to avoid overheating or electrical failure. For settings exposed to water or high humidity, such as outdoor installations or bathrooms, Environmental Factors like moisture resistance come into play. Therefore, opting for waterproof or weather-resistant connectors becomes a prudent choice.

Wire Termination Techniques

In the realm of electrical connectivity, wire termination techniques serve as the methodologies that define how wires are affixed to connectors. Soldering is a popular technique that involves using a molten filler material to create a permanent, robust connection. However, it often requires specialized tools and expertise.

Crimping is another common technique that provides quick and reliable connections by deforming the connector around the wire, usually using a crimping tool.

Lastly, Twisting is often employed for temporary connections or in conjunction with wire nuts to secure multiple wire ends together. Each of these methods has its advantages and disadvantages, and the best choice usually depends on the specific use-case, the required durability of the connection, and the tools at hand.

Safety Considerations

Safety is not merely an afterthought but a crucial prerequisite when dealing with electrical systems and, by extension, electrical connectors. Best practices dictate that power should always be disconnected before beginning any electrical work to avoid electric shock or worse. It’s also advisable to use insulated tools to further mitigate the risk of accidental electrical contact.

Adhering to manufacturer guidelines for each specific type of connector ensures that the connections are not only secure but also meet safety standards. Remember, shortcuts and quick fixes are often a prelude to safety hazards. Therefore, taking the time to follow recommended safety procedures can save both time and lives in the long run.

Common Mistakes to Avoid

The path to efficient and safe electrical installations is often fraught with potential pitfalls. Some common mistakes include choosing connectors and wires of mismatched sizes, not providing sufficient insulation around the connections, and overloading connectors beyond their rated capacity. Such oversights can result in not only inefficient systems but also increase the risk of electrical fires or system failures.

Hence, understanding the specifications of the components you’re using and adhering to best practices is non-negotiable. Knowing what to avoid can often be as valuable as knowing what to do when aiming for optimal performance and safety in any electrical application.

Installation and Wiring Tips

The process of installing connectors might appear simple, but attention to detail is crucial for a successful and safe outcome. One tip is to ensure that wires are stripped uniformly for a reliable connection. Additionally, connections should be snug but not overly tight to avoid damaging the wire or the connector.

It’s also good practice to regularly inspect the quality of connections for wear, corrosion, or damage that could compromise the system’s integrity. By identifying and rectifying issues early on, you can avoid more significant problems later, thereby saving both time and resources.

Maintenance and Troubleshooting

A key aspect of maintaining an efficient and long-lasting electrical system involves regular upkeep of its connectors. For troubleshooting, inspect the connectors for signs of wear, corrosion, or other visual damages that might impact performance. Using a multimeter can also help verify the continuity of a connection, assisting in pinpointing any faults.

Prompt replacement of faulty connectors is essential for preventing more severe issues from arising, such as system failures or safety hazards. Proactive maintenance and timely intervention are indispensable for ensuring that electrical systems function seamlessly and safely over the long term.

Innovations in Connector Technology

The domain of electrical connectors isn’t static. Over the years, there have been several advancements making them even more efficient and safer. For instance, newer connectors come equipped with improved insulation materials that not only enhance safety but also boost performance. There’s also a rise in the use of smart connectors that feature diagnostic capabilities, allowing for real-time monitoring and proactive issue detection.

Furthermore, design advancements have drastically reduced the time and effort required for installation, making the entire process more user-friendly. These ongoing innovations emphasize the ever-evolving nature of the electrical world and underscore the importance of staying updated with the latest technologies and practices.

Conclusion

While they might be small components in the vast arena of electrical systems, electrical wire connectors hold a place of paramount importance. Their role in ensuring the seamless flow of electricity, coupled with their safety contributions, cannot be overstated.

As we’ve traversed their intricate world, the significance of making informed choices, adhering to safety protocols, and keeping abreast of the latest technological advancements has been evident.

Equipped with this comprehensive knowledge, one can navigate the realm of electrical installations and maintenance with a higher degree of confidence, ensuring that all endeavors are both successful and safe.